Supply Chain Leadership Driving Industry 4.0 & Resilience During Crisis

Whilst the COVID-19 pandemic spreads across the world, it is vital for organisations to ensure a reliable supply of products and services. Lockdown of cities and manufacturing plants have significantly impacted many industries’ supply chains. This challenge has contributed to the slowdown or cessation of production in some sectors (e.g. fashion, automotive, spare parts, airlines). But has also created employment opportunities in others (e.g. retail, e-commerce, food production). At the same time, communities struggle to survive through curfew periods and other restrictions to secure products affordably whilst complying with health and safety conditions.

COVID-19 has dramatically influenced consumer behaviour. The rush to stockpile basic needs like food, beverages and toilet paper led to a dramatic increase in sales at retail outlets such as supermarkets. This not only triggered demand volatility, but also raised a significant question mark in managers’ minds about the status of demand after the crisis. Consumption in the crisis was initially supported by panic-buying. This in turn, triggered online sales, the re-emergence of weekly grocery shopping habits and additional pressures on supply chains.

It is therefore critical to ask how should supply chains be managed during and after crisis to ensure availability? What actions should leaders take to manage supply chains for least cost and least risk, as well as to prosper from opportunities appearing due to the crisis?

LEADERSHIP IN SUPPLY CHAIN

Business leaders typically focus on optimising operations and partnership, gaining market share, advancing the use of technology and improving profitability. But the COVID-19 crisis, has required rapid operational solutions to unforeseen roadblocks. Quick solutions to employee shortages, remote working, and to ensure health and safety across the company need to be deployed. These bottlenecks significantly change the priorities of leaders.

In supply chain, leadership is critical in broad and diverse areas of actions. Team re-building, split of responsibilities/tasks, border closure challenges, quick navigation of stock management, prioritisation of logistics to consumer needs and coordination with partners upstream and downstream. It is not an easy for supply chain leaders to re-prioritise tasks in a short span of time. In such situations, leaders need to be very well organised

Put first things first. Circumstances vary by the hour and actions are time-critical in a crisis. Existing data and information might be incomplete and inaccurate, feedback from the team might be delayed. But decisions have to be taken anyway. Clarity is important on what is urgent in the current situation is crucial.

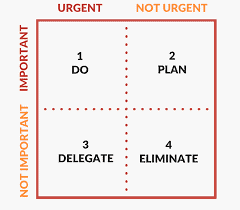

The Eisenhower Principle helps manage the decision-making process effectively in every situation. The Eisenhower Principle was founded by Dwight D. Eisenhower who was the 34th President of the United States from 1953 until 1961.

During a crisis important and urgent actions need to be categorised. Important actions lead to achieving operational and/or financial goals in business. While urgent actions demand immediate attention. These are usually customer-centric. Urgent and important activities may already be known or may appear at the last minute.

It is crucial for the leader to match responsibilities and tasks within the team to prevent burn out and ensure operational flow. Relying on our experience in the industry and academic field, it is worth to say that if everything is urgent, nothing is urgent! Thus, it is beneficial for leaders to prioritise tasks through The Eisenhower Principle and to delegate responsibilities across the team.

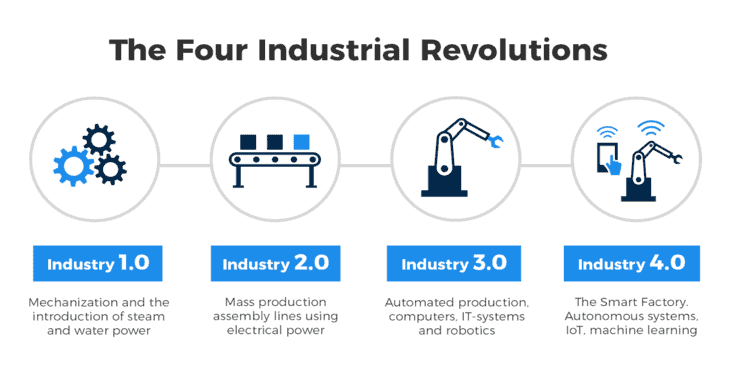

Industry 4.0. is beyond information technology and more about exploring what the customer wants. It helps the supply chain become compressed and tightly integrated through shortened life cycles, lead times and minimised operations’ cost. Supply chain leaders need to focus on three key areas to leverage the supply chain performance and to satisfy the demand in the market both during and after crisis.

DECISION MAKING

Innovation and supplier management calls for cloud-based integrated systems between partners and advanced predictive models. Supply partners’ integrated systems provide competitive advantage through shortened supply operations and speedy decision-making. Predictive analytics will quicken demand response and involve product-use insights to improve accuracy against external factors affecting demand (e.g. economic factors, consumer behaviour, the Covid-19 situation). Cyber Physical Systems (CPSs) are key enablers for Industry 4.0. It enhances communication and information sharing, along with real-time data collection not only through the supply chain but also from internal processes. These technologies are critical to understanding the requirements in the supply chain, lower lead times and increase customer satisfaction. For instance, suppliers can provide twoway early warnings, that increases responsiveness in the supply chain. Pricing decisions can be integrated with demand and supply planning. Predictive demand can propose prices changes, subject to stock levels and replenishment capacity. This boosts revenues and optimises inventory. In a crisis economic factors are critical. These are likely to influence shoppers buying choices. Foreseeing the pricing factor on the demand side is vital for organisations to address pricing policies.

Agility and visibility. In crisis, consumer demands become more complex and response to demand needs to be faster. This necessitates full transparency and increased visibility. Prescriptive analytics, where data constantly move in and out of partners’ systems, helps take data insights to the next level with improved visibility and for decision making. Digitalisation enables partners to track the entire supply chain in real-time (e.g. exact location of goods (on order, in transit, or in a warehouse)). Internet of Things (IoT) brings more connectivity in the supply chain network to advance visibility and agility to the logistics and supply operations. Radio-Frequency Identification (RFID) enables self-monitoring tools to monitor and communicates their real-time performance. This can be applied to inventory management, fleet and order tracking, ID badging. This helps improve order management and accuracy, shorten estimated transit times (ETAs) and minimise out-of-stock situations. Such end-to-end real-time visibility will enable partners to respond more swiftly to disruptions in real-time and minimise risk as well as confronting demand ambiguities post crisis.

Efficiency and cost management. Machine learning and big data analytics augments critical roles in efficiency, problem solving and cost saving. Data acquisition and filtering and scenario analysis are time consuming practices in supply chain. Automating these practices reduces workforce and expedites decision-making process for managers. Machine learning enable many transactions to be fully automated, which creates optimal decision making. Time to products restocking, automating repeat purchases could be made simpler by enabling a customer inventory demand to forecast while big data analytics enable real-time focus and simultaneous analysis of diverse data streams generating valuable information for forecasting and planning. This helps automatically reorder items on the buyer’s behalf based on pre-established alignment between partners accurately. This automation expedites replenishment cycle on shelves, reduces excess stock and workforce while optimising availability on the shelves, which in turn all will contribute to less costly operations and more profitable sales.

It is well known that consumers’ behaviour evolves after a crisis. People will be more meticulous about the traceability of goods from health and safety perspective. Industry 4.0 technologies can help track goods’ history throughout the blockchain. This helps organisations be more transparent to consumers and build in loyalty to their brands. All of the information about a product, its sub-assemblies, components, and its distribution path to market can all be traced transparently through blockchain.

In addition to Industry 4.0, leaders’ solid data analytics and interpretation skills emerge from obscurity during crisis. For instance, what are the top SKUs preferred by which customer, which supplier’s deliveries are reliable in relation to on time in full (OTIF), at product-, region-, or category-level? What is the share of business in the customer-product matrix? Which customer should be prioritised at SKU-, category- or channel-level through a route optimisation plan? Data can be extracted from systems but the analysis and interpretation for decision making relies upon the analytic skills of supply chain leaders.

Why do some companies have the ability to cope with crises better than others? They seem to be more resilient than others. It is the effective manifestation of unquantifiable risk in the supply chain. Resilience in supply chains that we address here is the ability of a company to deal successfully with abrupt situations throughout its supply chain. Since COVID-19 has affected many businesses and related supply chains, resilience has taken on even more significance in the supply chain. Companies can develop resilience in two main ways.

Act lean. The philosophy of lean, triggers us to look for the “Ideal Way”. So, we need to ask, “what is the ideal?”; it is perfect quality, zero waste, and happy satisfied customers. For companies not adopting lean, Peter Hines’s Six Rights seems to be a good start, which are Right Product, Right Place, Right Time, Right Quantity, Right Quality, and Right Price.

Arguably, it is criticised that acting too lean can cause breakdowns in crisis. Downsides of a lean approach are likely to be out of stock risks – reduced stock holding, cost of implementation, and transformation of workflows. In fact, regardless of crisis if barriers and/or failures appear in a lean approach, it is due to hierarchical or cultural factors. A lean approach calls for an inverted flow of ideas where front line staff members who face daily problems are at the heart of business. Therefore, organisations owning a top-to-bottom approach are likely to face these challenges more compared to organisations following a bottom-up approach. Organisational culture represents the common values, beliefs and behaviours for a common way of thinking and acting. While lean thinking requires collaborative actions and culture adoption, organisations who cannot embed the lean principle into their culture are likely to fail.

Since the first day Jeff Bezos created Amazon, he has adopted a customer-centric philosophy through lean thinking. Amazon’s supply chain heavily depends on the outsourcing of its inventory management. Products we infrequently order are not stored in regular Amazon warehouses. Almost 82% percent of sales are through third-party sellers, which is around $42.75 billion (based on 2018 sales). When we closed the doors due to COVID-19 for more than a month, one of the options was to spend time reading books. In UAE, the well-known bookstores are Amazon and Borders. Since we could not go out, the first port of call was likely Amazon. On the other hand, Borders took around almost more than a month to initiate home delivery, limited at first to Dubai and then other cities in UAE. In other words, being lean does not only help companies to improve resilience and improve efficiency, but also improve responsiveness to opportunities when they appear in crises.

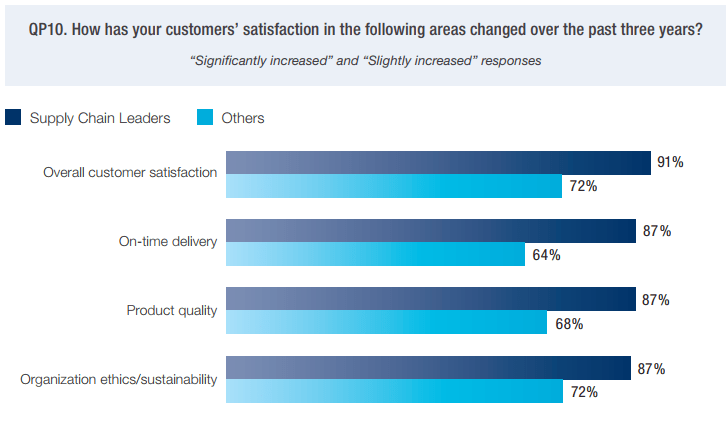

Customer Centricity. Customer centricity is not about setting a company strategy through the forecasted demand of the product portfolio in the market. Rather building the ability to be able to clearly understand what exactly customers want and act upon these insights as soon as possible. In early 2020 Oxford Economics conducted research to explore how supply chain leaders can minimise risks and maximise opportunities.

From a survey of 1000 executives worldwide, they identified a group of supply chain leaders who exhibited customer-centricity as one of four traits leading to more effective, resilient, and better-performing supply chains. The figure below shows that the customer satisfaction levels of those companies with these supply chain leaders focussing on stronger customer-centric strategies are much higher when compared to other companies.

Being customer-centric enables companies to improve sustainability and uplift manufacturing through higher quality products and strengthen logistics, which results in higher levels of on-time deliveries. This directly affects customer satisfaction and therefore improves customer retention and loyalty. For instance, due to COVID-19, a massive demand appeared for ventilators. The white appliances manufacturer in Turkey, Arçelik, re-organised its manufacturing place in a limited time to be able to initiate ventilator production. Arçelik collaborated effectively with companies from different industries, like Aselsan and Biosys in order to identify, design and supply all required raw materials locally. This illustrated the supply chain flexibility at Arçelik. The company not only finished the first prototype in less than a month but also produced 3,626 ventilators and exported 1000 of them.

CONCLUSION

Handling pressure in times of crisis with calmness and assuredness whilst spreading same traits’ attitudes in personnel across the organisation is a key characteristic of good leadership. Supply chains are complex, fragile and have several controllable and uncontrollable factors, most of which rely on big data and analytic decision-making. This calls for an analytical thinking and decision-making mindset. Leaders who are knowledgeable about technology, business tools and techniques, have capabilities of foreseeing what markets need in the future, as well as an ability to uplift team spirits in crisis. These will be the ones that provide competitive advantage to organisations.

Without investment in Industry 4.0, it is not going to be easy to remain competitive in the market moving forward. Beyond the cloud-based integration of systems, the goal is to advance reachability of demand, transparency to consumer needs, and common decision-making of supply partners on real-time data sets in the supply chain. Both predictive and prescriptive analytics’ systems are essential to be part of future supply chains.

Resilience in supply chains is mandatory to cope with crisis situations. A lean approach is a good point to assist in the call to resiliency. With the aim of looking for an ideal way, it is timely to offer right product at the right place in the right time with right quantity and quality for a right price. This approach calls for a customer-centric mindset, the vision of which puts supply chain at the front of business when it comes to decision-making for maximum customer satisfaction. However, when applying the lean approach, organisations should ensure they embed lean thinking to their culture and at every level of hierarchy.

References:

- Fatorachian, H and Kazemi, H. (2020), Impact of Industry 4.0 on supply chain performance. Production Planning & Control. DIO: https://doi.org/10.1080/09537287.2020.1712487, pp.1-19.

- Muller, J.M (2019), Contributions of Industry 4.0 to quality management – A SCOR Perspective, IFAC Papers Online. pp.1236-1241.

- Oxford Economics and SAP (2020). Surviving and Thriving. How Supply Chain Leaders minimize risk and maximize opportunities. Oxford Economics & Sap. oxfordeconomics.com pp.1-15.

- Wrong, M., (2007) in IFIP International Federation for Information Processing, Volume 246, Advances in Production Management Systems, Olhager, J., Persson, F., (Boston: Springer), pp.413–422.

For citation:

Eksoz, C. and Hubbard, N (2020), “Supply Chain Leadership Driving Industry 4.0 & Resilience During Crisis”. The Official Journal of The Logistics & Supply Chain Management Society. Iss. 47, July 2020: 37-43.

Sorry, the comment form is closed at this time.

Marietta Ross Tyne

This design is wicked! You definitely know how to keep a reader amused. Marietta Ross Tyne

Revkah Manolo Camille

I really like and appreciate your article post. Fantastic. Revkah Manolo Camille

Julianna Reynard Buxton

Some genuinely nice and useful information on this internet site, as well I think the pattern contains great features. Julianna Reynard Buxton

Concordia Zane Demeyer

Somebody necessarily lend a hand to make seriously articles I would state. That is the first time I frequented your web page and up to now? I surprised with the research you made to create this actual put up extraordinary. Excellent job! Concordia Zane Demeyer

Glenine Kurtis Standford

Pretty nice post. I just stumbled upon your blog and wished to say that I have really enjoyed surfing around your blog posts. In any case I will be subscribing to your rss feed and I hope you write again soon! Glenine Kurtis Standford

JOKER GAMING

If you are going for best contents like I do, only go to see this web page all the time because it presents feature contents, thanks Domini Scotty Prudi

Blessphemy Cover

This article presents clear idea for the new people of blogging,

that really how to do running a blog.

bedava hesap

bedava hesap arayanlar için açılmış bir internet sitesidir.

Üye olmadan kolay bir şekilde ücretsiz hesap alabilirsiniz.

Free hesap dağıtımı yapıyoruz ve beleş alabiliyorsunuz.

İsterseniz ücretsiz hesapları kendiniz de

oluşturabilirsiniz yada bedava hesaplar ile web sitemizden kolay bir şekilde kopyalayıp alabilirsiniz.

bedava hesap

almazan kitchen

Oh my goodness! Amazing article

dude! Many thanks, However I am having problems with

your RSS. I don’t understand the reason why I cannot subscribe

to it. Is there anyone else having

identical RSS issues?

Anyone who knows the answer can you kindly respond?

Thanks!!

Beth

Very nice post. I just stumbled upon your blog

and wanted to say that I have truly enjoyed surfing

around your blog posts.

After all I will be subscribing to your feed and I hope you write again very

soon!