Five Pillars to Save Cost in Today’s Supply Chain (Part 2)

In the first part of this article, I spoke about the 3 pillars of setting goals (but have a plan), centralise, and collaborate to minimise cost in supply chain from different dimensions. While setting gaols with concrete plan was representing a roadmap of an organisation in terms of being clear from where and when to save cost and most importantly how, meaning a plan required to save cost.

The second pillar of centralisation was more related to the structure of supply chain. As per my experience in supply chain organisations, centralisation always surpass decentralisation. It enables the organisation to manage all operations under one umbrella which in turn speed up decision making, flow of operations and coordination both internally and externally. Finally, I talked about the importance of collaboration. Working on join goals should not be limited to partners at upstream and downstream level, but also with third-party organisations, such as 3PL, transportation, and/or custom clearance organisations. Collaboration not only helps saving cost but also sharing risk in supply chain when it is managed effectively on a single plan.

In part two, I addresses the rest of two pillars which are critical for successful cost saving for supply chain organisations.

- AUTOMATE

THE FIRST RULE OF ANY TECHNOLOGY USED IN A BUSINESS IS THAT AUTOMATION APPLIED TO AN EFFICIENT OPERATION WILL MAGNIFY THE EFFICIENCY. THE SECOND IS THAT AUTOMATION APPLIED TO AN INEFFICIENT OPERATION WILL MAGNIFY THE INEFFICIENCY! – BILL GATES

In addition to the complexity of supply chain and limited visibility to demand in many industries, a new generation of shopping options through e-Commerce and continuously evolving consumer behaviours had made supply chain management a fatal area of concern for many businesses. It is particularly critical for manufacturing companies and distributors, which are heavily dependent upon their supply chain partners to deliver right product in the right quantity, in the right condition, at the right place, at the right time, to the right customer, and at the right price. With an increasing emphasis on automation, as well as the changes in customer expectations, the need for an integrated supply chain has become increasingly important and requisite to cope with obscurity.

For manufacturing companies and distributors, to build a substantial customer base, digitalise business processes, ensure up-to-date information flow and exchange across the chain has become more of a necessity than a value-add proposition. Supply chain solutions can enable companies to build end-to-end automation that not only speed up processes and avoid bottlenecks in the supply chain, but also purvey timely and accurate information flow, which in turn eases timely decision making. Bringing automation to supply chain management leads to manage and enhance the exchange of information of across departments and supply chain partners. With correct choice of inventory management solutions, excess inventory and obsolete products can be minimised, the areas of which most companies encounter with such costs affecting cash flow significantly. Through automation, efficiency in production and transportation can also be improved, and this directly enhances customer service with meeting customer needs in an efficient manner.

For manufacturers, for instance, having automation in supply chain increases visibility at up-stream and down-stream level. This provides longer eye sight to required procurement budget, production capacity and manpower. This in turn eases the control of product flow, improves maneuverability against delays and problems, and of course minimises scrap and excess production cost. Inventory control and optimisation is another significant occasion to save cost through automation as well.

In today’s volatile market, it is not pragmatic to keep same stock level through the year anymore while demand fluctuates from month to month and is affected by many factors. This not only causes excess stocks and obsolete items, but also increases risk of sales miss. Such problems are fully capital blockage for supply chain partners. With automation, it is possible to have sliding targets stock levels at SKU, brand or at division level, where target service level to trade enables to set most efficient stock level through the year. Such practices provide substantial contribution to the business with increased stock turnover, maintained freshness of products, improved warehouse utilisation capacity in addition to increased customer satisfaction.

Egmont, for instance, is one of the largest specialist in children’s book published in the UK and over one million children reads their publications every month. Egmont has over 1200 articles, all of which are manufactured in the UK, Europe and the Far East. The challenges of Egmont were limited access to manual reports, difficulty of predicting not only consumer behaviours but also rapidly changing trends and fashion. These challenges were causing excess stock that are no longer sold by retailers, and in return it was massive cost for them.

Egmont’s collaboration with Eazystock has helped the company to integrate all data from key business platform, to use historical sales data in a more sophisticated way for better forecasts, and to improve visibility from production till the stock level of their distributors. As a result, Egmont achieved to reduce its stock by 10 percent within ten months, differentiated high and low selling articles, and categorised their product portfolio based on revenue and sales performance. Automation at Egmont not only increased flexibility with reaching data at any time via mobile application, but also standardised the reporting system with arranging routine email systems to have reports whenever and wherever needed.

Automation is also key facilitator for better collaboration in supply chain. Tracking product and information flow through the whole supply chain enables supply chain partners to ensure transparency, continuous visibility and better forecast for future demand, which in turn helps building trust and commitment among the partners as well.

Another benefit of automation is about effective order tracking and delivery. It is timely to remind that higher customer satisfaction levels lead to higher customer retention. Automation has a vital role in increasing speed of delivery and in keeping the customer informed about the product delivery schedule. In today’s automation systems, supply chain partners can design processes to keep customers informed throughout the process, from order confirmation to order fulfilment. There are supply chain solutions that enable customers to track their order while transferring customer service tasks to the customer, which in turn save time and money for companies. This practice can apply manufacturers and their logistic providers to get real time updates on shipments of arrival, clearance and even reach to warehouse.

TRAIN (YOUR PEOPLE)

TRAIN PEOPLE WELL ENOUGH SO THEY CAN LEAVE. TREAT THEM WELL ENOUGH SO THEY DON’T WANT TO! – RICHARD BRANSON

Many organisations see employee training as an expense rather than investment. Have you ever check the cost of NOT training your existing employees? I bet only limited number of companies are aware of the size of expense shown up when not training employees.

Untrained employees clearly have limited knowledge and ability to reach against company sources, proactively reach against evolving business dynamics and environment referring to competitors, consumer behaviours and other external factors. This increases risk of human error, slows down processes and, in return, affects customer satisfaction and retention, with missing sales in the long-run.

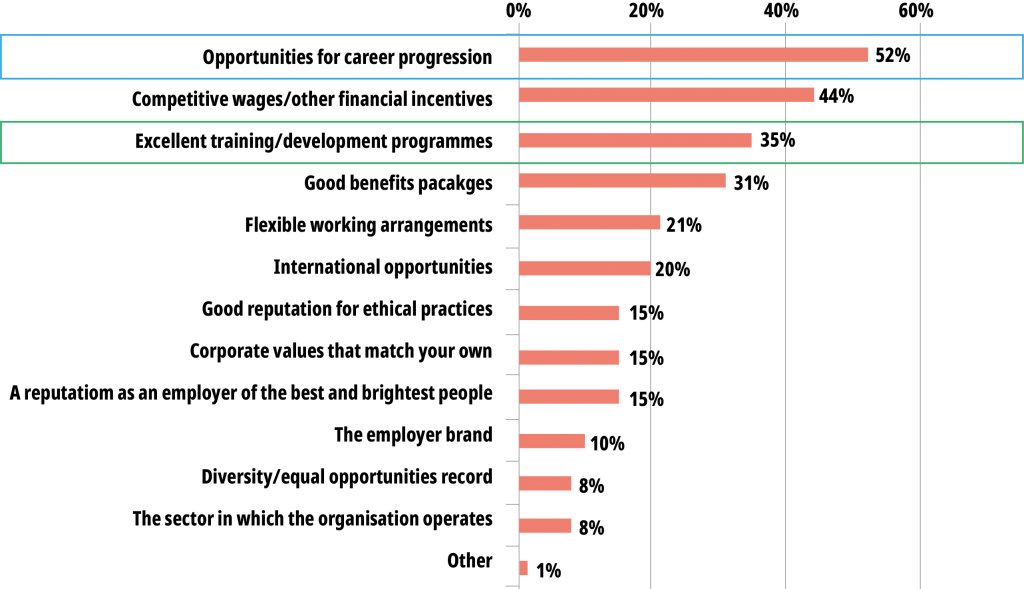

To make customers happy, you should make employees happy first. Based on research conducted by PwC, it has been asked Millennials: “Which of the following characteristics make an organisation compelling to work for?” according to the survey. The third most important characteristics demanded by millennials has been found as excellent training and development programs, representing 35 percent of participants. The current and up and coming generation strongly believes in the value of the opportunity to be promoted in position as well. It is clear that new generation is aware of the competitive world we live in, thus a job in organisations that provides training opportunities satisfies their need to stay ahead of the curve.

Untrained employees feel unappreciated in the job. At that level, employee either deliver poor performance, which causes higher cost, or leave the organisation. It might seem easier to replace employee with a new hire, but according to research, cost of new hires reaches up to 30 percent of related position’s salary[1]. On the other hand, training an existing employee might only cost of few hundred dollars and takes far less time, not considering the cost and time spent during adaptation period of the new hire. According to studies, cost of re-hiring represents approximately 12 percent of an organisation’s expenses, and this percentage can reach up to 40 percent for organisations having high turnover[2] . Employee turnover has one of the most critical elements on the success of organisations, and it has negative effect on the financial statements.

It should not be forgotten that performance of your organisation is as good as the performance of your employees. High quality and pragmatic trainings run by professionals, who clearly understands the needs of industry, will enhance employees’ ownership, because of feeling valued and increased motivation, will minimise multiplications and errors, and enhance customer service, which in turn improves retention and higher sales. Not to mention that employees’ loyalty to the organisation is also correlated to the value given to him/her, calling for training was well.

It might have perceived overwhelming to provide a weeklong training course to employees, but there are much better alternatives, which aim at improving the skills and knowledge of employees for hands on execution in practice. For instance, Muscat University, the Faculty of Logistics & Transport, delivers Executive Education Programs purely for practitioners that rolls from one to five days. The program runs its executive courses in partnership with Cranfield University and Aston University from the UK, and aims at providing best-in-class logistics, supply chain, and inventory management courses which are highly pragmatic, enable hands on execution in practice, and are enriched with real problems from industry and relevant theories from the literature to close the knowledge gap of practitioners who are in junior-, mid- and top-management role in the Middle East.

Schlumberger, the world’s leading oilfield service provider, and Muscat University, for instance, have signed Memorandum of Understanding in several disciplines including but not limited to high quality programs and training courses focusing on the industry, but also industry driven research and development programs in several fields.

In conclusion, supply chain is getting more complex each passing day, factors affecting demand-supply accrue day by day while consumer expectations evolve massively from market to market. In such circumstances, saving cost is the most critical requisite for profitability. In order to achieve this, it is essential to have specific, measureable, realistic and time-based gaols. But goals without a plan is just a wish. A proper and solid plan needs to be developed to support the goals.

Today’s business also needs more centralised control than a decentralised approach. Having only one tone of voice in supply chain helps have a clear road-map to be followed while central decision making is likely to improve your company’s flexibility when managing ambiguities through the chain.

Importance of automation also should not be underestimated for long-term savings, yet this does not necessarily mean the replacement of manpower with IT systems. Instead, automating routine supply chain operations, standardising process, optimising inventory and logistics operations call for investment to IT. When having automation, it is essential to provide effective training to employees for increased productivity.

Training is no longer about sending all managers away for a weekend conference or sending employees to a one-week lecture in a hotel. Effective training needs to be tailored to employee and business needs and to be an ongoing venture. It should be provided by trustworthy institutions or universities which can support organisations from multiple subjects and areas, such as research, placement, and training, have official accreditations.

Global competition and ever-changing technology necessitates that skills need to be continuously updated to keep manpower ready for tomorrow. Human Resources Departments undertake a critical role on this, and they should make it a priority to encourage and promote employees’ training while keeping the amount of time spent away from work to a minimum.

References:

Jonsson, P., Rudberg, M., Holmberg, S. (2013), “Centralised supply chain planning at IKEA”, Supply Chain Management: An International Journal, Vol. 18, No. 3, pp. 337-350.

Bensberg, J. (2019). Egmont Improves Forecasting, Reduces Stock and Optimizes Inventory Management with EazyStock. Case Study: Egmont Publishing.

Res Digital (2019). The True Cost of Poor Training. Resolution. Retrieved from: https://res.digital/the-true-cost-of-poor-training/

For citation:

Eksoz C. (2020) “Five Pillars to Save Cost in Today’s Supply Chain (Part 2)”. The Official Journal of The Logistics & Supply Chain Management Society. Iss. 44, February/March 2020: 27-32.