How Can An Enabled Partner Collaboration Deliver A Higher Performance?

The market is dynamic, consumer behaviors are inconstant and evolve each passing day which in turn makes demand fluctuated while both internal (organisational) or external (environmental or economic) circumstances escalate existing obstacles. This prevents supply chain partners, here manufacturers and retailers, from building long term business plans, and in return increases a risk of managing working capital in an optimal way.

Manufacturers, for instance, faces challenges such as:

- Accurately projecting purchase of raw-materials for on time and in full production of demand

- Holding just enough stock level for both raw-materials and finished goods

- Regulating optimal production capacity without missing demand with less cost

- Achieving accurate lead time both in production and transportation

- Ensuring quality of finished goods while competing with time and cost

On the other hand, retailers strive to overcome difficulties, such as

- Minimizing inventory holding costs· Ensuring 100% availability on shelves

- Optimizing shelf utilization with best-selling SKUs

- Achieving timely shelf replenishment with minimum cost at stores

OK, but how partners should make better decision in such a hazy business environment to improve profitability and reduce inventory cost? For partners, it is inevitable to cope with such challenges alone, and this calls for the importance of collaboration. Therefore, I would offer two collaboration practices for supply chain partners, which are Collaborative planning, forecasting and replenishment (CPFR), for external collaboration between partners, and Sales and Operations Planning (S&OP), for internal collaboration addressed between departments.

Collaborative planning, forecasting and replenishment (CPFR)

CPFR is a collaboration platform for retailers and suppliers where they can synchronize their business plan, forecasting process and replenishment operations. The goal here is to enhance product availability and to reduce inventory and delivery costs through:· Aligning demand and supply with effective information sharing· Managing processes based on partners’ exceptions, and· Meeting end-customers’ needs with a strong sales and marketing plan The collaboration of Wal-Mart and P&G is a good example from practice, where they jointly develop forecasts and replenishment operations, and gain favor by improving information sharing and reducing the waste of consumer goods. The CPFR aspect consists of the three prime processes of planning, forecasting and replenishment. These processes constitute four important stages to improve the collaborative performance of manufacturers and retailers.

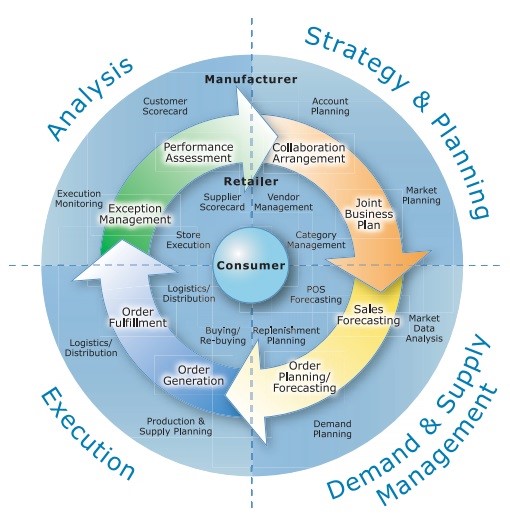

Figure 1. CPFR Model – Manufacturer and retailer tasks

Source: (VICS, 2004)

1) Stage 1: Strategy & Planning

Identify baseline rules for collaboration and select product-groups merchandised by developing a joint business plan for a particular period.

At this stage, partners set a collaboration frame as a guideline to jointly align on a single process flow that will be followed to synchronize both parties’ goals. Since this stage is the basis of collaboration, parties should:

- Define clear goals and objectives

- Identify systems to be used through collaboration

- Define target product-groups, responsible business functions and accountabilities

- Clarify types and frequency of information to be shared mutually

- Set Joint Key Performance Indicators (KPIs)

- Set a calendar for the review of KPIs and corrective action plans

- Publish front-end agreement to be signed by top-management

2) Demand & Supply Management:

Share Point-of-Sales data and additional sources to fulfil the forecasting and shipment requirements over the period

The latter stage is dedicated to joint forecast building process, where parties mutually exchange information for joint demand planning, (including data purification, joint promotion plans and special events via marketing calendar, shelf share, etc). Once all related data is ready, parties build forecast upon agreed forecast horizon that covers all related sales and marketing plan. The recommendation here for both parties to follow different forecasting approach when generating forecasts, and then jointly align on single demand plan at the Distribution Centre or Store Level. For instance, the retailer can generate forecasts with bottom-up approach with aggregating SKU level forecasts to know required demand at Store Level. Manufacturer, on the other hand, disaggregate forecasts from Distribution Centre or Store level to SKU level. Once parties merge plans developed from different approaches, it will help them to explore potential factors that likely to affect their demand, which in turn help make corrective adjustment for higher forecast accuracy. The following in this stage is to return demand plan to shipment forecast by manufacturer to ensure timely replenishment of stock to Stores and Distribution Centres.

3) Execution: Set orders, share delivery plans and consider the number of products in stock and on retail shelves. Then, record sales and make payment

The Execution stage is rather an operational synergy of parties that continuous actions for each operations are discussed, aligned and executed in a constructive way with meeting both sides’ expectations. This stage calls for transparency and full of visibility by both parties with rationales for exceptions, and most importantly requires collaborative decision making to contribute to parties’ mutual goals.

4) Analysis:

Track the joint business plan in comparison with the execution progress made.

The final stage of CPFR is dedicated to the review of KPIs set on a single calendar. Partners should arrange continuous meetings to review joint KPIs, analyse progress made so far, define existing challenges, and jointly develop corrective actions plans with clear accountabilities to be reviewed for the next meeting.

Despite of these stages, as the guideline of CPFR, practitioners are likely to confront significant challenges through the implementation of CPFR. These challenges are primarily to choose correct partners and relevant products, set up a performance measurement policy, settle and synchronize partners’ organisational approach, and join the different goals on a joint KPIs.

Partners not only confront external dynamics (e.g. economic conditions, unexpected events, seasonality and promotions), but are also involved in internal dynamics that appear due to poor organisational structure (e.g. lack of data, poor information systems and communication). Such disturbances occasion excess stock, Out of Stock, and/or expiries. Hence, inter-organisational interaction is important to manage demand against such shortcomings and product-related ambiguities. The following section therefore addresses the collaboration practice of S&OP that partners need to apply within their organisation which help them to integrate their business plan with partners in a most efficient and constructive way while providing internal alignment between departments.

Sales and Operations Planning (S&OP)

S&OP is an interdepartmental level platform to coordinate information sharing, constructively align on the sales and promotion plan, and to convert demand plan to operations activities for better demand-supply alignment with partners. Its objectives are to analyse the performance and objectives of relevant departments to ensure they proceed with a single outlook, and to align the company’s demand forecast and supply-service practices via integrated business plans.

S&OP starts with pre-established meetings of salespeople to build demand forecasts, referring to target sales. Then, forecasts are adjusted based on marketing plans, including advertisements, promotions, newly launched products and potential risk of obsolescence. Afterwards, the operation department considers the forecasts of salespeople to generate inventory, supply chain and production plans to meet forecasts. Finally, the S&OP meeting is held with representatives of sales & marketing, operations and finance departments to finalize the future S&OP plan, and to identify the meeting cycle alongside responsibilities. Given the dynamic structure of existing market we trade in, manufacturers need to be more agile in the operations of information sharing, forecasting and production. Building a good internal coordination with S&OP is likely to enhance their capability of rapidly reacting to instant demand changes in the market.

Whilst S&OP is more a planning focused internal approach, CPFR moves this practice to the external level by creating consensus between partners, where it further evolves partners’ supply chain from a scanty push system to a more customer focused pull system systematically. In practice, the collaboration of The Lowe’s Home Improvement and Whirlpool is a good example of the combination of CPFR and S&OP. Partners initially worked on customer focused marketing strategies for better order forecasts and inventory levels. Then, the focus became the alignment of sales and forecasting plans, which also helped them to be involved in promotions, launching new items and planning special events. Such a linkage of CPFR and S&OP enabled Whirlpool as a manufacturer to enhance sales growth by 12 percent, to reduce inventory costs by 5 percent and to improve timely deliveries by 3 percent along with increased flexibility and faster decision making.

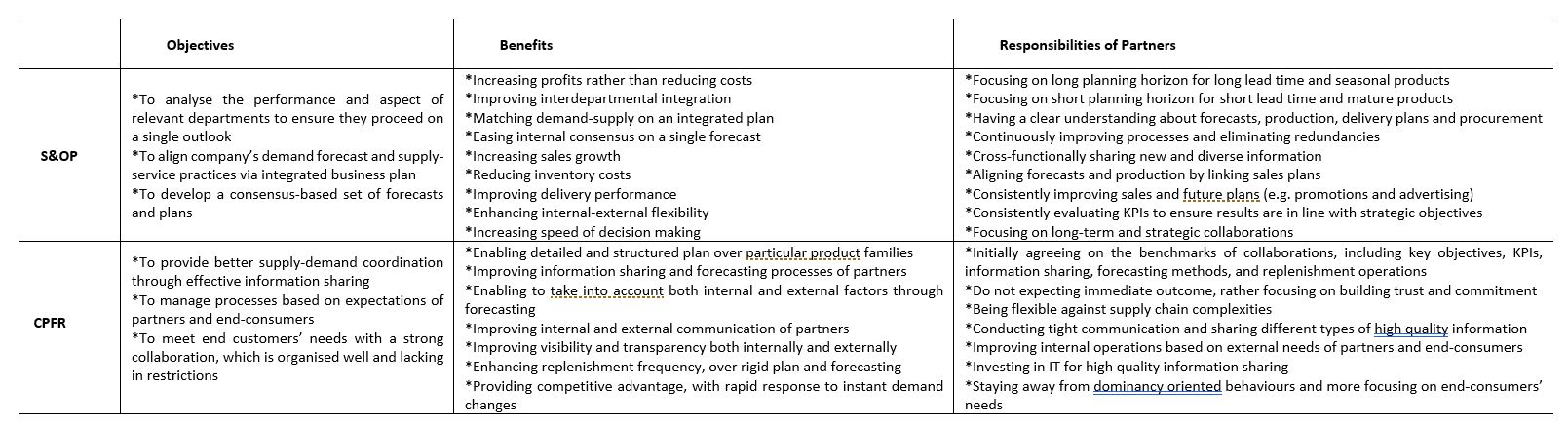

Table 1 is a guideline for practitioners to know more about objectives, benefits and required responsibilities when it comes to applying CPFR and S&OP during collaboration

Table 1. Collaboration landscapes: Objectives, benefits and the accompanying responsibilities of partners during CPFR and S&OP

For Citation:

Eksoz, C. (2019) “How Can An Enabled Partner Collaboration Deliver a Higher Performance?”. The Official Journal of The Logistics & Supply Chain Management Society. Iss. March 2019 : 39-43.