Three-Levels of Partnerships in Dyadic Supply Chains

Supply chain management is a vital part of business that leads firms to systematically coordinate the flow of products, information and finances to meet end-consumers’ demand. Managing the supply chain in today’s fast-paced environment is a challenging effort due to increased competition, fragile economic conditions, and continuously evolving consumer behaviors.

Long lead-times, limited visibility at the upstream and downstream levels, with demand uncertainties are only some of the barriers that supply firms strive to cope with in today’s business environment. On the other hand, partners investing in partnership advances their supply chain with a competitive advantage. Firms like Unilever, Kraft, Tesco, Sainsbury’s, Kimberly Clark and Whirlpool are only some of the firms that gained successful competitive advantage from partnerships. Wal-Mart and Sara Lee Branded Apparel partnership led to increased sales by 45% and market share by 10%, while Nabisco and Wegmans partnership led to sales growth by 32% and inventory reduction by 18% (source: Ireland and Bruce, 2000).

Partnership is a resource-sensitive and effort-driven practice that needs mutual trust, commitment and continuous communication. When executives and senior managers aim at building collaboration with partner firms, the foremost consideration should be the manifestation of corporate goals and objectives. Then, it should be determined whether these goals and objectives are compatible with partner’s goals and objectives.

When manufacturing firms aim to improve production with minimum production and inventory costs, distributors focus on higher service levels at the downstream level, with minimum cost of inventory and logistics operations. On the other hand, retailers aim at minimizing inventory costs whilst maximizing availability on shelves and of course sales. It is critical for supply firms to leverage on tangible benefits of partnerships. Understanding the mutual goals and objectives are about trade-offs between cost of supply chain and service performance. Since partnership is a matter of collaboration, I would categorize it as operational-, mid-, and strategic-level partnership.

- Operational-level partnership focuses on improving operational efficiency and effectiveness between supply firms. Whilst improved efficiency leads to minimize the usage of resources, effectiveness in partnership is more about improved ability to deliver goods and services at the acceptable level of end-consumers. This partnership needs exchange of information for better visibility on demand and supply operations, made separately by parties. Whilst the intervention of top- and senior management is minimal, improving supply chain performance is a primary goal, which is expected to be delivery, speed, consistency in operations, and flexibility to handle customer service requests.

- Mid-level partnership is the level of collaboration practice where partners are not necessarily to define mutual goals and objectives, but rather to involve their process planning through high level engagement of senior management. Since the focus of each party is to achieve their mid-level goals and objectives (e.g. sales target, inventory levels, fulfillment rate, etc.), partners need to monitor performance at the customer and supply level. Although strategic decisions are made separately, efficient communication, sharing of resources and planning are essential whilst committing to collaborative benefits.

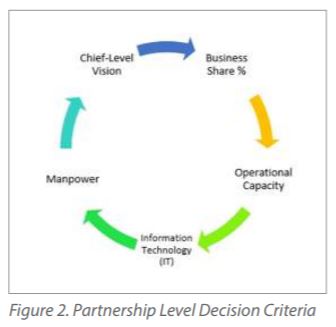

- Strategic-level partnership is the level of collaboration practice that involves complex demand, supply and sales planning. This requires a more sophisticated relationship built on a high level of trust, understanding and flexibility. Commitment and support of top-management are mandatory in order to integrate partners’ goals within a single business plan. I call this a Partnership Book to achieve long-term but mutual goals and objectives. Clear definitions of responsibilities, information types and frequency of sharing resources as well as smart Key Performance Indicators (KPIs) to measure collaboration performance are vital for continuous improvement of relations. Organisations can get benefit from three different types of partnership. Depending on the infrastructure and functionality of firms, they should aim at building correct partnership level. But, how to decide which partnership is the best for your organization? To answer this question, I do recommend the following five criteria;

HOW CAN ORGANISATIONS IDENTIFY WHEN TO TRIGGER INTO PARTNERSHIP ENGAGEMENT LEVELS?

- Business Share (%) We first need to identify the partners/ company that give a significant contribution to your organisation – main case being that provide revenue or gross profit. A level of at least 20% of revenue or gross profit, be candidates to develop strategic-level. The mod level partnership would targeting functional dependencies, which should be about 30% of impact.

The operating level partnerships could account for 50 targeting more on transactional efficiencies. Updating this partnership mapping periodically is crucial to strengthen the decision that will be made to invest in correct partnership level.

2. Operational Capacity The present marketing environment is fast-paced and purely demand driven. Partners have to be responsive against any fluctuations and volatility on demand. This is because, the partner firm’s production and distribution capacity undertake a key role on the implementation of correct level of partnership. Success rate of operational capacity is recommended to be evaluated based on Pareto principle, which will show the 20% of products leading the 80% of business or sales. If the partner firm’s operational capacity meet the 80% of sales on time with full fill rate, there is a great potential to collaborate at the strategic-level.

Managing capacity saturation will be vitally important to partnerships. Each side should work on the way of justifying the resource commitment through the investment required for either mid-level or operational level partnership. Lead-time of finished goods or raw materials at the upstream level also play a vital role on the operational capacity, thus on time alignment for order placement, shipment and replenishment of finished goods will help partner firms to find the best way of meeting demand.

3. Information Technology (IT): Today’s business is built upon IT and calls for different IT tools and systems for accurate, on-time and relevant information exchange between partner firms. The sources of demand, supply and production planning are the information that flows among partner firms. The more accurate and timely information exchanged, the better planning executed for collaboration. Insufficient IT is a limiting factor for the strategically aligned companies. Partners’ agreement on the information types and the conditions of sharing information will be one of the factors of deciding the level of partnership. Each side will have to make the adequate investments to ensure that their capabilities to the partnership can be sustained. Reluctance or inadequate levels will put the partnership in jeopardy. Continuous review and engagement in such areas will be crucial.

4. Manpower Collaboration needs willingness, time and continuous effort put into the practice. It calls for highly skillful, knowledgeable and also flexible employees and leaders to contribute to the collaboration. Having limited manpower is likely to limit number of collaborations conducted with

Particularly, strategic-level partnerships need good personal sources to establish the frame of partnership and to lead complex processes for win-win relations. Therefore, a significant requisite is to appoint correct leaders to the partnership development process. Today’s leaders are responsible from articulating a vision, motivating people to act and focusing on problem solving. Partnership development rather seeks leaders who can safeguard the process, facilitate constructive interaction and are capable of dealing with high levels of frustration. Leadership in a collaborative environment is completely different from hierarchical position. The leaders in collaboration embrace the positive change despite of complexity. They are open to all viewpoints, focus on consensus-building, and are passionately optimistic. Instead of aiming at individual recognition and unilateral acquisition, sharing knowledge, power and credit is priority for collaborative leaders. They motivate partnership teams to excel, and to develop a keen understanding of key benefits in partnership.

Building strategic-level partnership calls for leaders who lead productive and goal-oriented meetings. They use each opportunity for sustainable exchange of perspective, with ensuring full contribution of team members. These leaders are the ones that strategically put the unified vision of firms to the practice with a great harmony of resolving conflicts and disagreements. Leader and manpower is a significant factor for not only deciding the correct level of partnership, but also ensuring the longevity of partnership.

5. Chief-Level Vision One of the distinguishing features for strategic alignment is to combine the long-term objectives of partner firms in a single plan. This requires a clear and unified vision of top-management. Both parties’ CEOs’ or GMs’ continuous support to their collaborative teams are vital on the success. The benefits of strategic-level partnership do not appear in the short-run, but rather manifest in the long-term. Chief-Level people’s vision shared with their teams and openness to investment are vital.

Lack of vision by top-management is the most limiting factor of strategic level partnership. Once the thinking and strategy is aligned, the Chief Level team should share this vision with their collaborative teams that are responsible for execution of the vision into sustainable goals and objectives. A framework of goals, the objectives and required investment extended over time, is the foremost duty of the Chief-Level people. Strategic-level partnership involves complexity and sophistication whilst higher degree of trust and commitment is mandatory from both parties. The continuous pursuit of progress is necessary by Chief-Level people. Their regular involvement with collaborative teams will also streamline the sense of rationale for investment required for partnership.

IN SUMMARY, PARTNERSHIPS IS THE WAY TO GO BUT NEED CAREFUL CONSIDERATIONS

The key focus of developing partnership, is to gain a competitive advantage in today’s challenging and competitive business environment. Although investment at different levels seems requisite, the return on investment over the period of time is worthwhile.

Operational-level partnership is a good option that aim at improving delivery speed, having consistency in operations and handling customer needs resiliently. Whilst mid-level partnerships need more engagement of senior management to make them work effectively. The successful deliverables expected are growth in sales, savings from inventory costs and better service levels. Strategic-level partnerships are the most complicated and time consuming agreements for all parties. However these should yield the higher long-term benefits as they cover a deeper engagement touching sometimes the fundamentals of an organisation’s structure, tools and enablers. Despite all the hard work in setting up any type of partnership level, it also has an important intangible that good leaders recognize.

It is a way to grow and accelerate the maturity of the people in their organisations. Beyond, all the other strategic benefits, the visible improvements in their long-reaching predictability through better planning and risk management due to joint forces, commitment to and trust built in the partnership.

References:

- Ireland, R. and Bruce, R. (2000) ‘CPFR: Only the Beginning of Collaboration’, Supply chain management review, 4(4), pp. 80-88

For Citation:

Eksoz, C. (2017), “Three-Levels of Partnerships in Dyadic Supply Chains”, The Official Journal of The Logistics & Supply Chain Management Society, Iss. Feb.17, pp.32-35.